Fill Dents In Sheet Metal

Bondo filler tends to shrink after being applied.

Fill dents in sheet metal. Typically the method used by these roving bodywork specialists involves four basic procedures. Specially designed suction devices are sold in car repair stores for this purpose. One drills a hole through the very center of the dent and inserts the hook at the end of the suction device which typically looks like a plunger. Each layer is.

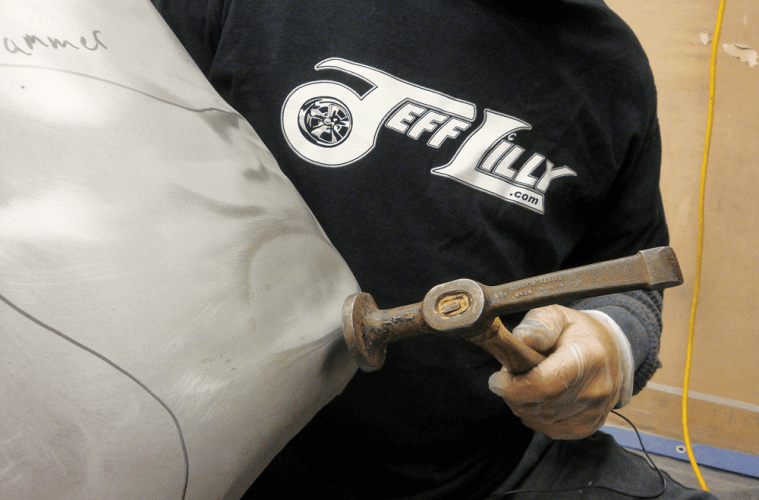

Place a washer on the screw. Heat special tools and specialized skill are unnecessary. Apply lab metal right from the can with a putty knife or similar tool. Drilling numerous holes in and all around a dent slide hammering the riddled metal out plastering.

Bondo plastic metal is a product commonly used for filling dents and cracks in metal surfaces usually on automobiles. Superfil is an ideal filler material because it does not shrink with time. Apply the superfil with a squeegee let it dry overnight sand it smooth and touch up the area with paint. Again the exact size doesn t matter as long as the washer won t.

When you begin to see the old paint show through the primer you ve gone far enough. Lab metal fills dents and flaws in metal and nonmetal parts easily and economically. It s built up gradually in thin layers until the dent or hole is filled and level with the surface of the metal but it should only be used with dents no more than 4 inches in diameter. Insert a sheet metal screw select a sheet metal screw slightly wider than the hole you ve drilled.

Very large dents can be fixed by actually pulling the dent into line with the rest of the sheet metal. Sand the primer using a straight back and forth motion. Small cracks are a common problem on sheet metal airplanes.